Last month the ECOPRO project was launched at the Technological University of the Shannon (TUS), Athlone Campus.

Led by Dr Chaitra Venkatesh, the kick off began with research overviews from TUS research institute directors, highlighting the universities diverse expertise and research capacity.

Presentations were delivered by Dr Declan Devine, Director of the PRISM Research Institute, and Dr Margaret Brennan Fournet, Director of the LIFE Research Institute.

Following these overviews, the ECOPRO team commenced key project updates, including a summary of the project's progress, a communications strategy update, academic partner updates from Avans Hogeschool and Munster University, in addition to an industry partner update from Delta Q.

Dr Kees Kruithof, lead at Avans Hodgeschool presented their methodology to synthesising high-performing colorants. Tests to determine the lightfastness of the developed colours and the results were presented along with project plans to advance the use of these colours in industry-standard polymers.

Dr Julia Wessels, lead at Munster University presented the biological degradation and toxicity aspects of the developed colorants and the coloured polymers. They outlined the work plan for the colour extraction and the compost experiments in this project.

Chris Small gave an overview of the DeltaQ facility and their expertise in colour masterbatch production. As an industrial partner, he outlined the expectations and criteria necessary for optimising the developed colours to meet industry standard with high Technology Readiness Levels (TRL).

Following the meetings, the ECOPRO team attended the TUS Engineering Expo, where 168 undergraduate projects and 25 PhD projects were displayed. These projects covered a wide array of cutting-edge fields, including robotics, virtual reality, artificial intelligence, sustainable design, and electric vehicle development.

Applied Polymer Technologies Facility Tour

The team then toured the Applied Polymer Technologies facility, examining the array of equipment and machinery used for the project. Discussions ensued regarding various processes for the project and the quantity of colourant required for initial trials and subsequent pilot-scale production.

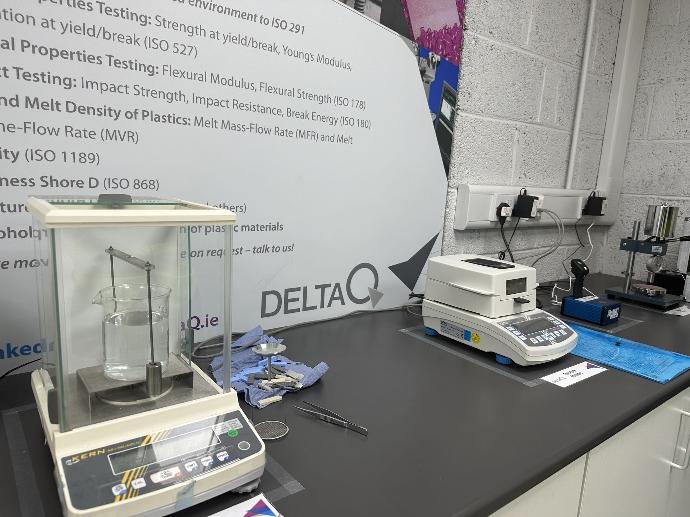

Delta Q Facility Tour.

Finally, the team toured the DeltaQ facility, viewing a range of colorants displayed and the equipment used for processing and testing the colour masterbatch they produce. They observed the ongoing processing of the colorant granules and discussed the issue with colour fastness and strategies to address them at the early stage of our project.